Manufacturing Facilities

Our manufacturing consist of latest technique machines, auto control pickling facility, Auto cont bell annealing furnace, technically qualified staff & workers. The complete production processes have been developed thoroughly and are screened for consistency in quality at each stage.

Manufacturing Facilities

- Dry Drawing Machines having size range of 1.40mm to 10.00mm

- Bull Blocks having size range of 5.00mm - 30.00mm

- Auto Bell Annealing Furnaces (Austria Design)

- Auto control pickling & Pre-coating Baths ( Seven tank Process)

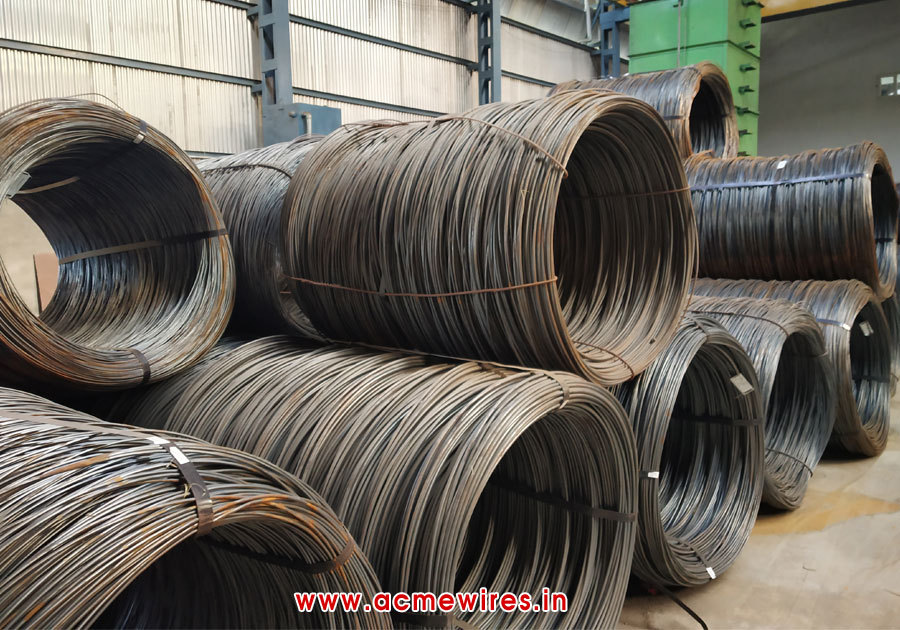

- Good space under shed to store raw material

- Auto Packing of three activities at a time of Finish wire coils

- Forklifter (Toyata ) for safe handling of wire bundles.

Material Testing Equipments

Digital Tensile Testing Machine - Capacity 200KN - One No.

Digital Tensile Testing Machine - Capacity 50KN - One No.

Torsion Testing Machines - One Nos.

Analytical Weighing Balance - To check chemical properties

Strohlein Apparatus - To check % of Carbon - One No.

Digital Micrometers (Least Count =0.001mm) - To check Diameter of wire - Two Nos.

Vernier Caliper (Least Count =0.01mm) - to check % RA of Wire Rods as well as Wires - One No

Microscope & their accessories (100X - 1000X): One No.

NOTE: ALL THESE EQUIPMENTS ARE CALIBRATED THROUGH EXTERNAL NABL ACCREDITED LABS

Call Us now at +91-9878100119 +91-9876500612

To get more information about our products, please email at: acmewiresldh@gmail.com